- CBCT imaging details the regional anatomy of a potential surgical site.

- Digital dentistry combines CBCT imaging with CAD/CAM and 3-D printing technology.

- Precision surgical intervention is made possible by proper implementation of this technology.

- Oral & Maxillofacial Radiologists’ CBCT Reports ensure pathology-free anatomy for the clinician to implement this technology safely.

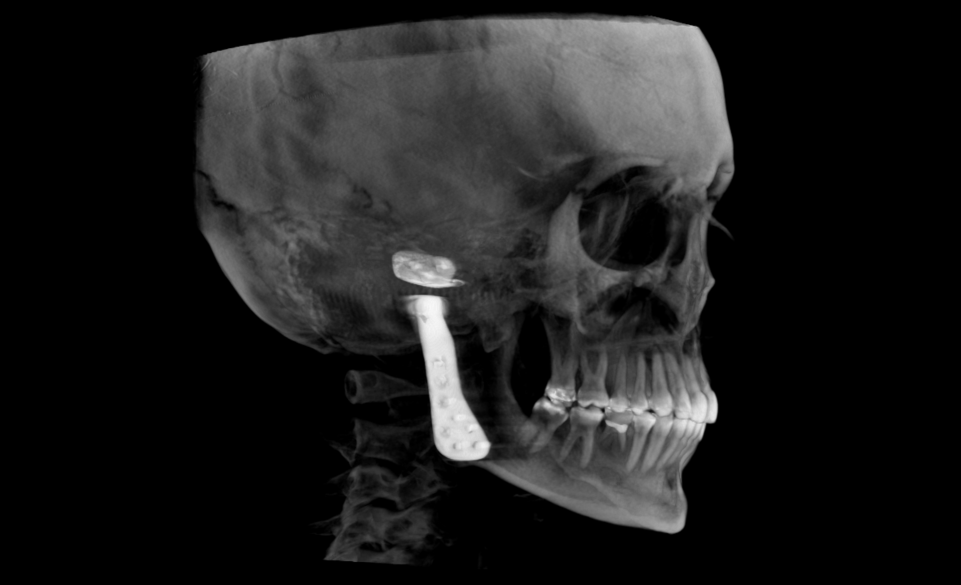

Cone-beam computed tomography (CBCT) is a medical imaging technique that uses X-rays to create three-dimensional (3D) images of a patient’s anatomy. CBCT has become a valuable tool in surgical planning because it provides high-quality, detailed images that allow surgeons to visualize the patient’s anatomy in 3D, and by integration with 3D printing technology they can even hold a model of it in their hands! This “digital dentistry” framework has significant implications for delivery of care, and the impact on surgical planning cannot be overstated.

The degree of surgical planning depends primarily on the reason for intervention and the anatomy potentially involved. An example of where CBCT provides no value is the case of a patient needing a small fibroma excised from the lip – the soft tissue contrast in CBCT imaging is inadequate to offer any diagnostic value, and the concern for regional anatomy is minimal for excision of such a superficial benign lesion. As for a patient with an Ameloblastoma preparing for unilateral resection of their mandible, surgical planning should be extensive.

While the most obvious reason for CBCT imaging (or really any diagnostic imaging) is to narrow the differential diagnosis, the digital nature of CBCT data sets facilitates integration with additional digital data. For example, the patient with an Ameloblastoma mentioned above would surely benefit from mandibular reconstruction after resection, and CBCT plus 3-D printing makes this process better than ever! CAD/CAM technology has been around for a while and has had wide adoption – digital impressions and milling units have granted patients the ability to have same-day crown treatments and enhanced the practice of orthodontics with clear aligner technology. 3-D printing is a remarkable advancement and rapid adoption is anticipated.

Stereolithography is a process of converting digital files into physical models via 3-D printing data sets of .stl files. Digital radiography data is stored with DICOM (.dcm) files. The process of DICOM segmentation and conversion into .stl files allows for existing anatomy to be 3-D printed. This model could be used to prepare the metallic reconstruction scaffolding in advance, all but eliminating the time required to do so during the operation. Further, by designing the surgical margins pre-operatively – and in the presence of the proper biocompatible materials – the anatomy to be resected can be digitally replicated and 3-D printed in advance for delivery at the time of surgery.

This technology has many applications, not solely for large operations. A patient needing a single tooth implant to replace a missing molar in a narrow mandibular body could have an implant surgical guide prepared for precision placement. Using CBCT images, implant size, position, and angulation can be prescribed to fit within the existing bone without risk to adjacent anatomy. Segmentation of the anatomy allows for export and subsequent design and 3-D printing of the surgical guide for use during implant placement.

Edentulous patients can benefit from this technology as well. Dentures can have a series of radiopaque markers applied. Each denture can then be scanned with CBCT on a platform. The patient can then have the dentures (with the markers unmoved) seated in the mouth and a CBCT of the patient can be acquired. Utilizing these imaging data sets in capable software, the patient’s jaw position can be marked, their dentures can be digitally removed, and implant surgical guides can be created using just the maxilla and mandible data. If osseous reduction is needed for restorative space, this can also be planned along with 3-D printing of surgical reduction guides.

The use cases for this digital technology continue to expand. Advances continue in all phases and aspects of this process. CBCT scans are generating higher quality images with low radiation exposure techniques, software integration is becoming more seamless, and 3-D printers are fast, accurate, accessible, and more affordable than ever. Implementation of this technology in the practice of dentistry will be fun and rewarding, especially with a level of patience during the learning phase.